Huatian Aviation Power: Standardization Path of Gas Turbine Participation in "Hydrogen Energy Storage"

Hydrogen energy is a new trend in global energy transformation and development, and an important component of modern energy systems, which will have a profound impact on the prospects of energy applications in China. The commercialization pace of the global hydrogen energy industry is constantly accelerating, and energy giants from various countries are competing to layout the hydrogen energy industry.

Huatian Aviation Power aims at the development direction of the global hydrogen energy industry and focuses on hydrogen combustiongas turbineWe have conducted in-depth research on the technological development and practical application of gas turbines, and compiled this article in order to provide reliable technical support and practical experience for the widespread application of gas turbines in the field of hydrogen energy.

As the world moves towards net zero carbon emissions, the installed capacity of intermittent renewable energy generation (especially wind and solar energy) is rapidly developing. How to integrate intermittent renewable energy in the best way to ensure power supply security has become a global topic.

The energy storage logic of hydrogen combustion

The increasing installed capacity of renewable energy sources has made the balance of power grid resources more complex. Although energy storage batteries have become an increasingly popular choice, using hydrogen as an energy carrier willHydrogen energy storageCombining with gas turbines to ensure optimal use of intermittent renewable energy also has significant appeal.

The cutting-edge concept is to use excess wind and solar energy to produce water through electrolysisGreen HydrogenStore it for use in gas turbine hydrogen power generation to achieve zero carbon and dispatchable power generation. Essentially, green hydrogen can serve as a storage form for wind and solar energy.

Standardization development of hydrogen combustion transformation in gas turbine power plants

All green hydrogen technologies currently being researched by global gas turbine manufacturers, including the production, storage, and application of green hydrogen in gas turbines, are mature commercial technologies. The challenge lies in scaling up these technologies and enabling them to enter the market faster.

At present, several global gas turbine manufacturers are transforming gas turbines in the power sector and making steady progress in using hydrogen gas. In September 2020, Mitsubishi Power launched what is claimed to be the world's first integrated green hydrogen "standard package", supporting the transition of traditional gas-fired power plants to hydrogen energy. Other host manufacturers around the world have also been collaborating with customers, gradually launching their own "standard packages" and developing a standardized solution for hydrogen retrofitting in all gas-fired power plants. The 'standard package' solves the complex problems that power generators and grid operators may encounter when integrating renewable energy, gas turbines, green hydrogen, and other energy storage technologies. This will also help reduce costs, expand scale, and increase market acceptance.

The content of the relevant standard package mainly focuses on the following aspects.

In terms of overall renovation of power plants

Reduce renovation costs by sharing public auxiliary systems. When constructing an electrolytic cell system, the existing cooling water system, softened water system, and many electrical equipment of the power plant can be shared. Through this synergistic effect, it helps to reduce system complexity, improve operational efficiency, and reduce investment costs.

In terms of physical integration

One is to integrate the design of rectifiers, transformers, buildings, and all other auxiliary equipment; Secondly, research is being conducted on how to utilize the waste heat of gas turbines in the dismantling of electrolytic cells and gas turbines. For example, providing low-grade heat to the electrolytic cell to help improve its start-up and operational efficiency.

In terms of digital integration

When integrating and installing all other devices, seek standardization of digital integration.

Mitsubishi Electric's Standardization Practice Case

Mitsubishi Electric is offering a green hydrogen solution called the "Hydaptive Standard Flexibility Package". The Hydaptive suite aims to provide flexibility in renewable energy through near instantaneous power balancing resources, greatly enhancing the ability of simple cycle or combined cycle power plants to increase/decrease power and strengthen grid balancing services.

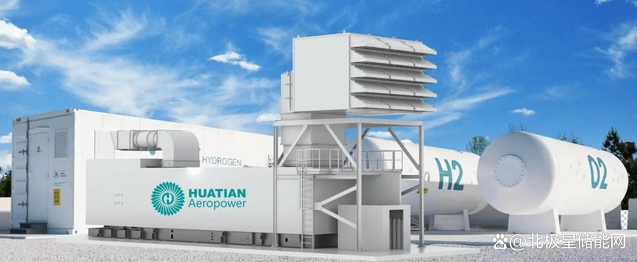

It integrates a gas turbine power plant with an electrolytic water hydrogen production unit, while combining on-site hydrogen storage to produce 100% renewable electricity. In addition, TOMONI software and controls achieve fast load response by integrating gas turbines and electrolysis devices. The Hydaptive suite adds expandable/expandable storage capabilities that can be used for new gas turbine power plants or retrofitting existing power plants to improve flexibility and extend asset life.

China's attempt at "standard package"

Huatian Aviation Power, in collaboration with relevant clients and research institutes, has compiled the "Blue Book on Global Technological Development of Gas Turbine Hydrogen Power Generation" and systematically proposed a domestic version of the "Standard Package" for hydrogen energy transformation of gas power plants, which mainly involves the following aspects.

Hydrogen fuel transportation and storage safetycomplete

The large-scale uninterrupted transportation of hydrogen through natural gas pipelines is considered the most convenient and effective. However, hydrogen has a wider explosive limit and faster combustion rate than natural gas. In addition, hydrogen has a deteriorating effect on metal materials. The safety issues of using existing natural gas pipelines to transport mixed or pure hydrogen fuels urgently need to be addressed.

To ensure that the output of the gas turbine remains unchanged, the volume flow rate of natural gas in the pipeline needs to be increased by 3.3 times. Therefore, it is necessary to increase the pressure drop of the pipeline and enhance the transportation capacity of the fuel. However, adverse factors such as the embrittlement characteristics of hydrogen on metal materials and the permeation of hydrogen are severely compounded in high-pressure operating environments.

So the requirements for transporting hydrogen or mixed hydrogen fuel are particularly high for the pipes and their processing technology. Once existing pipelines are used to transport hydrogen or mixed hydrogen fuel in the future, they must be re inspected, repaired, updated, and regularly inspected for defects.

The large-scale storage of hydrogen in power plant areas is inevitably a major hazard source, subject to layers of supervision by various departments. In order to reduce the occurrence of risk accidents, the best mode of hydrogen power generation is to produce and use it immediately, eliminate storage links, and reduce potential hazards in intermediate processes.

Transformation of Hydrogen Gas Turbine Combined Cycle Power Plant

When the percentage of hydrogen content in the fuel is low, it has almost no impact on reducing CO2 emissions, so the industry hopes to achieve the application of 100% volume hydrogen content fuel as soon as possible.

During hydrogen combustion, the reactivity of hydrogen (flame propagation speed) increases, which may increase the risk of tempering; A shorter ignition delay time may increase the risk of accidental spontaneous combustion; Compared with natural gas, the thermoacoustic amplitude level and frequency of burning hydrogen are also different, which may have an impact on combustion stability.

At the same volume, the heating value (LHV) of hydrogen is lower than that of natural gas, which means that a larger volume flow rate of hydrogen is required to operate at the same thermal power; Burning hydrogen also increases the moisture content in the exhaust gas, leading to an increase in heat transfer to the hot end components and requiring more cooling; An increase in moisture content can also make hot corrosion more likely to occur, which may shorten the service life of certain components.

NOx emissions

Due to the high flame temperature of hydrogen, introducing hydrogen into existing combined cycle power plants may result in NOx emissions exceeding the limit. The solution is as follows:

SCR: Ammonia or ammonia derivatives are used as reducing agents, added to flue gas and reacted on catalysts to convert NOx into nitrogen and water. For existing gas turbine power plants, if SCR equipment has been installed, they may have some ability to withstand the increase in NOx emissions. Otherwise, the only option is to modify the SCR or increase the capacity of the installed SCR.

Steam dilution: When steam is used as a diluent, diffusion burners are already capable of processing hydrogen rich or even pure hydrogen fuels. However, steam dilution requires a large amount of high-purity water, additional energy to generate steam, and may increase the stress on the hot end components of gas turbines due to increased heat transfer.

At present, the research focus on hydrogen gas turbines is on the premixed burner of dry low NOx (DLN) technology.

space

The renovation of hydrogen fired power plants requires widening pipelines and changing materials to accommodate higher volumetric flow rates and prevent hydrogen embrittlement. In the renovation, there is not always space to accommodate wider pipelines, so if the power plant is likely to operate with hydrogen in the future, larger diameter pipelines should be built to accommodate the required amount of hydrogen.

The volumetric energy of hydrogen is about three times lower than that of natural gas, so hydrogen will occupy more space while providing the same energy. It is necessary to store some hydrogen gas on site to maintain the continuous operation of the power plant. This will affect the general layout of power plants and require additional space, as a safety zone is also needed around the hydrogen storage tanks.

The current electrolysis plant is unable to continuously provide sufficient hydrogen to ensure the continuous operation of large gas turbine power plants. For example, currently, the NEL M5000 is one of the larger hydrogen electrolysis cell equipment, which can only meet 1.2% of its demand for a 571MW GE 9HA.02 heavy-duty gas turbine that burns 100% hydrogen. However, as the market adapts to the increasing demand for hydrogen, this situation will continue to improve, but if hydrogen is to be electrolyzed on-site, space issues will arise.

pipe

When transporting hydrogen through pipelines, it is important to consider the delivery pressure and temperature to avoid hydrogen embrittlement in pipelines and auxiliary equipment. Hydrogen is usually compressed to between 35 bar and 150 bar for pipeline transmission; Distribution systems that provide gas to many end users typically operate at pressures below 7 bar. Larger diameter pipelines may provide equal mass flow at lower pressures.

Fuel Processing

Due to hydrogen being a very light gas with very small molecules, it can diffuse into certain materials, including certain types of steel pipelines, and increase the risk of their failure. Compared to large molecules such as natural gas, small-sized hydrogen molecules are also more likely to escape through seals and connectors.

Due to the continuous decrease in natural gas levels in fuel, flame detectors capable of detecting hydrogen flames can be added and gas sensors capable of detecting the decrease in hydrocarbon levels can be upgraded.

In general, it is necessary to modify the enclosure and ventilation system to reduce the risk of explosion and fire.

Establish standards and specifications related to fuel treatment in hydrogen power plants.

other

Due to the possibility of higher exhaust energy from hydrogen gas turbines, it may be necessary to adjust the waste heat boiler (HRSG), which is an important capital expenditure.

In general, extensive updates to the control system are required, which may affect the performance of the gas turbine, including output power and thermal efficiency.

If the power plant has a long-term service agreement, it is necessary to discuss with the service provider whether the hydrogen content in the fuel can be increased due to the potential increase in maintenance costs.