Golden Bell Cover for Heavy duty Gas Turbine Blades - Thermal Barrier Coating

1、 Preface

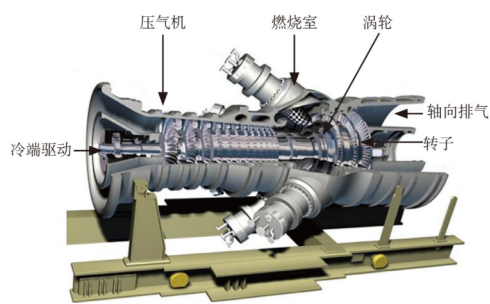

Due to its high thermal power conversion efficiency, heavy-duty gas turbines are the most core equipment in the fields of energy generation and ship propulsion. The development technology of high-grade heavy-duty gas turbines is extremely complex, so heavy-duty gas turbines are also known as the power heart of China's industrial and shipbuilding fields. Up to now, China has successfully developed a 50 MW heavy-duty gas turbine, achieving a breakthrough from scratch for the F-class 50 MW heavy-duty gas turbine. At present, China is increasingly improving the construction of the three major systems of heavy-duty gas turbines, achieving a trinity of prototype design, equipment manufacturing, and experimental delivery. China has also become the fifth country in the world to fully master the design and manufacturing technology of heavy-duty gas turbines.

In order to improve the high-temperature oxidation and corrosion resistance of gas turbine blades and extend their service life, the concept of thermal barrier coatings was proposed by the NASA Lewis Institute in the 1950s, and a long period of exploration was carried out in the material selection and preparation process of coatings. In the early 1980s, significant breakthroughs were made, laying a solid foundation for the application of thermal barrier coatings.

2、 Thermal barrier coating

Thermal barrier coatings are usually composed of a metal bonding substrate and a ceramic surface layer. The bonding substrate is usually made of MCrAlY (M is Ni, Co, or Ni+Co) alloy, which mainly serves multiple functions such as transition heat mismatch, oxidation resistance, and corrosion resistance. The ceramic surface layer is usually made of Y alloy2O3Stable ZrO2It mainly serves as a thermal insulation layer and has become one of the most advanced high-temperature protective coatings for heavy-duty gas turbines both domestically and internationally due to its excellent resistance to high-temperature oxidation, erosion, and thermal insulation.

With the development of the aviation industry, the thrust to weight ratio of turbine engines is increasing, and the inlet temperature before the turbine is also increasing. According to the research history of materials at home and abroad, it is quite difficult to achieve a significant improvement in the high-temperature resistance of turbine blades by increasing the material's operating temperature in a short period of time. A feasible method is to deposit thermal barrier coatings on the turbine blade substrate to increase its operating temperature. The future development of thermal barrier coating technology will focus on the following aspects:

① Research on a new thermal barrier coating material system suitable for the next generation of supersonic engines, seeking alternatives to ZrO2Ceramic materials with better phase stability, lower sintering rate, and thermal conductivity are key among them.

② Optimization research and mechanism study on the materials and preparation processes of existing coating systems, including the composition of Y bonding layer, selection of new stable oxides for YSZ ceramics, improvement and optimization of coating microstructure, as well as further research on gradient coating technology, in order to improve the working temperature, service life, and thermal insulation performance of coatings.

③ Research on the thermal insulation effect of thermal barrier coatings, through experimental simulation testing of the insulation situation of the coating, namely temperature gradient, combined with heat transfer theory, based on the thermal conductivity of the coating material, expected insulation effect, and working environment of the hot end components, provides a basis for the reasonable design of coating thickness and direction for coating improvement.

④ Further research on the life prediction model of thermal barrier coatings. If thermal barrier coatings are applied to high-risk areas of turbine engines, an engine life prediction system must be established to ensure safety. Therefore, further research on the failure mechanism of thermal barrier coating peeling and the mechanical behavior under service conditions is needed to establish a more comprehensive life prediction model, so as to accurately evaluate the service life of the coating and provide reliable guarantees for the practical application of thermal barrier coatings.

⑤ Develop new coating performance testing technologies, especially non-destructive testing techniques, to accurately characterize the adhesion between coatings and substrates, the degree of coating cracking, phase transformation, and other properties, in order to better control the quality of coatings.

3、 Thermal barrier coating monitoring

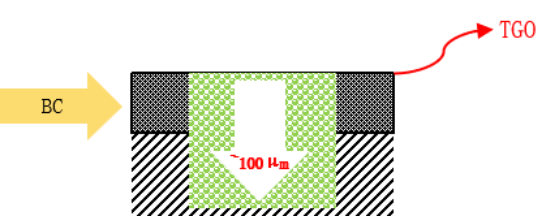

Thermal barrier coatings are mainly composed of a metal bonding substrate and a ceramic surface layer, with a complex structure. The element content and distribution information can be detected by glow discharge mass spectrometer.

Glow discharge mass spectrometer (GDMS) is one of the industrial instruments for analyzing high-purity substances. It is widely used for elemental quantitative analysis of high-purity substances, including trace level dopants and impurity analysis in high-purity materials in the microelectronics industry; Analysis of principal and trace components in pure metal materials, alloy materials, and superconducting materials; Analysis of block oxide powders and inorganic material insulators in other fields. In addition to quantitative analysis of elements, it can also be used for delamination analysis of materials.

Using GDMS to achieve longitudinal distribution analysis of TGO layer (~100 microns)

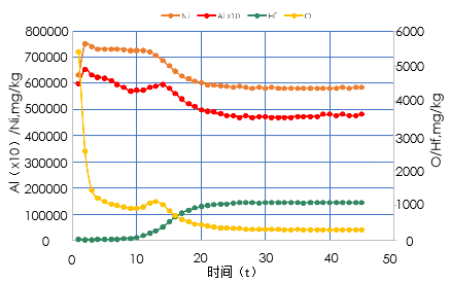

Distribution and diffusion behavior of main elements

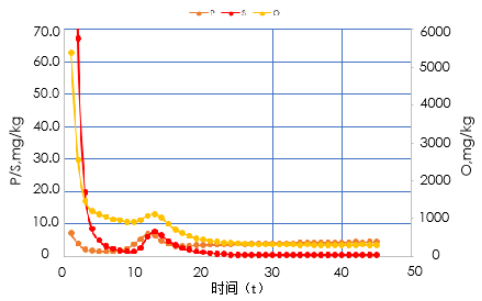

Monitor the distribution of impurity elements (including intentionally added harmful elements)