Research progress on erosion damage and protective coatings of aircraft engines

introduction

Main forms of erosion damage in aircraft engines | Anti erosion coating system for aircraft engines | Coating erosion test system | Conclusion and prospects

1、 The main forms of erosion damage in aircraft engines

The erosion damage of aircraft engines generally refers to the mechanical interaction between the surface of engine component materials and the impact fluid, resulting in gradual wear and tear of the material surface.

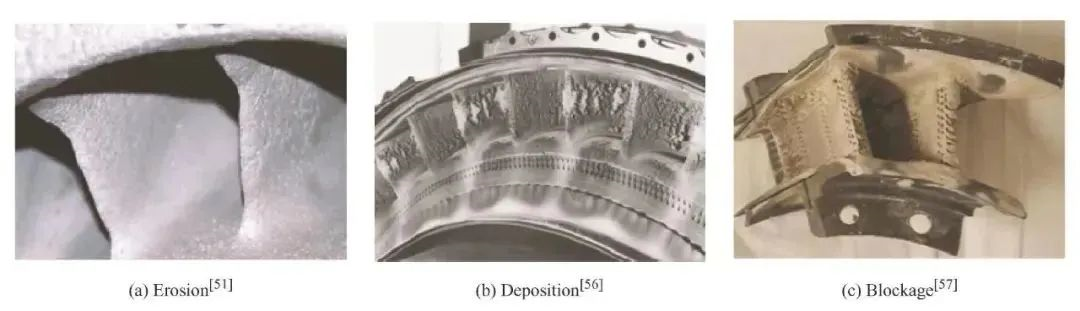

When an aircraft flies over the atmosphere, the forward facing surface of the engine may be affected by different particles or flying objects, especially solid particles and water droplets, which can directly or synergistically cause erosion damage to engine components and shorten their life cycle. These damages include erosion and wear of fan/compressor blades, blockage of blade cooling holes, dust deposition on turbine inlet guide vanes, aging of the fuel system, and deposition of carbon based substances on fuel nozzles.

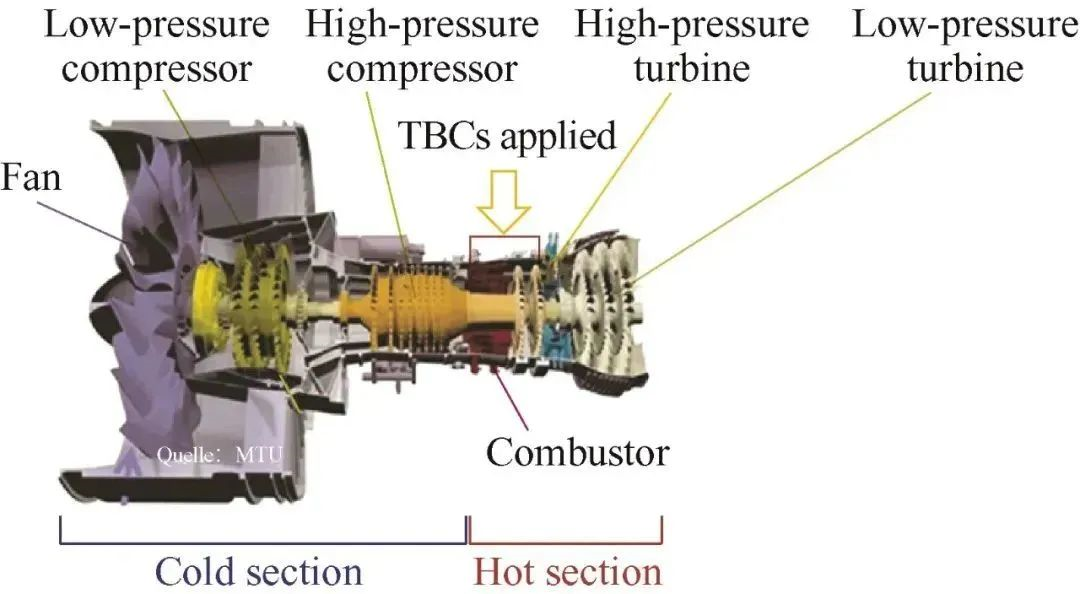

Due to differences in service environment, material properties, and spatial location, there are significant differences in the forms of erosion damage between the cold and hot end components of aircraft engines. The schematic diagram of the cold and hot end components of aircraft engines is shown in Figure 1.

Figure 1 Schematic diagram of cross-section of turbofan engine

Cold end components of aircraft engines

The cold end components of aircraft engines typically operate at temperatures below 600 ℃, including fan blades, compressor blades, and low-pressure turbines. During service, engines are susceptible to erosion damage caused by the impact of high-speed solid hard particles or high-speed liquid droplets.

01 Solid particle erosion

Solid particle erosion (SPE) refers to the damage phenomenon caused to the surface of a material by solid particles with a certain velocity and scale when passing through it.

The factors affecting solid particle erosion damage include particle size, particle velocity, erosion angle, erosion time, ambient temperature, mechanical properties of the eroded material, and material microstructure.

STACHOWIAK et al. summarized the failure modes of solid particles with different velocities impacting different materials at different erosion angles, including wear, fatigue, plastic deformation, fracture, etc.

The hard particles that cause erosion damage to the engine are mainly volcanic ash and sand particles. Volcanic eruptions can spray large amounts of solid and gaseous materials into the atmosphere, and follow atmospheric phenomena to move to higher altitudes and spread for more than two years.

Volcanic ash is mainly composed of hard and sharp rock fragments, often containing sulfides or aerosols, and even mixed with ice crystals and electrostatic charges in high-altitude areas, which can cause erosion damage to plastics, glass, and metals.

When aviation aircraft, such as military fighter jets or transport planes, are in high sand and dust environments, the intake filter of the engine cannot completely eliminate suspended particles in the air, as shown in Figure 2. Sand and dust will be sucked into the engine interior with high-speed airflow, causing erosion of fans, compressor blades, axial turbine blades, etc., resulting in a loss of work efficiency.

At present, solid particle erosion damage has become one of the most common types of damage in the service process of aircraft engines.

Regarding compressor blades that are greatly affected by solid particle erosion, relevant scholars have proposed the following theories based on extensive experimental accumulation and empirical models.

(1) Wear and secondary erosion

HE, BOUSSER, and others believe that during the dynamic process of high-speed airflow sandwiching hard particles and causing damage to solid surfaces, the impacted surface undergoes deformation, and the kinetic energy of the particles is partially or completely dissipated through various mechanisms such as plastic deformation, fracture, temperature rise, and phase transformation.

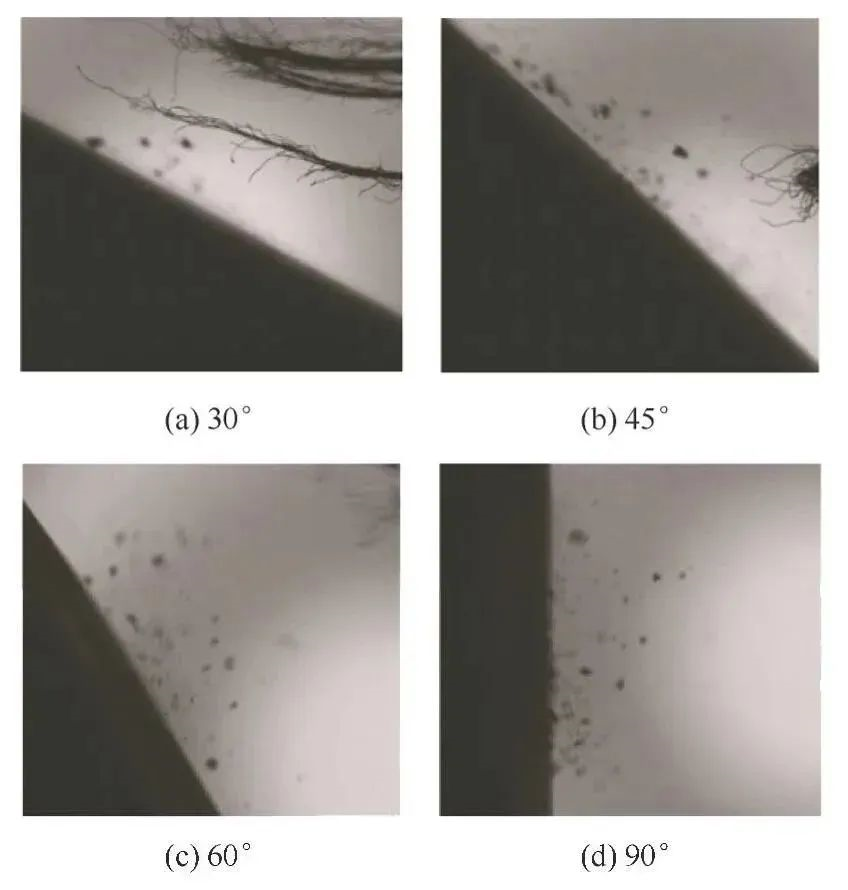

Generally speaking, for plastic materials, the main failure mode when small angle erosion occurs is micro cutting. For brittle materials, they are easily damaged when the erosion angle is large, and the failure mode is surface peeling caused by elastic-plastic deformation. As shown in Figure 3, hard particles rebound or break under the initial impact, and the broken particles with sufficient particle size and impact velocity impact the solid surface again, causing secondary erosion.

(2) High strain rate impact

HE, VOGEL and other studies have found that the compressor blades of aircraft engines are in a high-speed rotating state, and hard particles impact the blades at a relative speed exceeding the speed of sound, causing high strain and special damage to the blades.

The kinetic energy of the blades acting on the particles is large enough to separate and transport the particles or shattered particles generated by impact from the core flow of the fan into the bypass flow, causing additional damage to the blades.

Due to the highly complex process of particle blade interaction and particle fragmentation, there is currently a lack of further explanation.

Diagram of secondary erosion process

(3) Impact fatigue

HE, LI, and others believe that repeated impact of hard particles on solid surfaces causes stress concentration, resulting in microcracks or micro damages as fatigue sources. Fatigue crack propagation causes macroscopic damage to the solid surface.

The erosion behavior of solid particles is a complex dynamic process, influenced by numerous factors such as particle motion trajectory, erosion angle, solid surface stress state, and microscopic deformation. It is difficult to comprehensively consider all of these factors in practical erosion theory analysis.

Therefore, there are certain limitations and one sidedness in the establishment of erosion models, and accurately establishing a theoretical model for solid particle erosion remains a difficult point in this study.

02 droplet erosion

Rainwater erosion or droplet erosion (WDE) is generally defined as the damage behavior caused by continuous impact of droplets, resulting in the gradual loss of surface materials of engine components.

When the aircraft takes off and lands on a wet runway, passes through clouds or rainstorm, the high-speed airflow sucks in droplets and impacts the parts at the air inlet, causing strong erosion damage. For example, the blade will be impacted by droplets at a high speed (300~400m/s), causing surface damage, changing the leading edge profile and surface roughness, seriously affecting aerodynamic performance, causing thrust loss, increasing flutter risk, increasing fuel consumption and shortening the service life of the blade, which ultimately leads to the decline of engine efficiency.

In addition, droplets can also accelerate the erosion damage of solid particles on aircraft blades. Figure 4 shows the leading edge of the blade damaged by rainwater erosion.

Figure 4: Rainwater erosion damage on the leading edge of fan blades

BURSON, MA, FILD and others analyzed and summarized the erosion process caused by the continuous impact of high-speed droplets on solid surfaces such as fan blades.

(1) Direct deformation

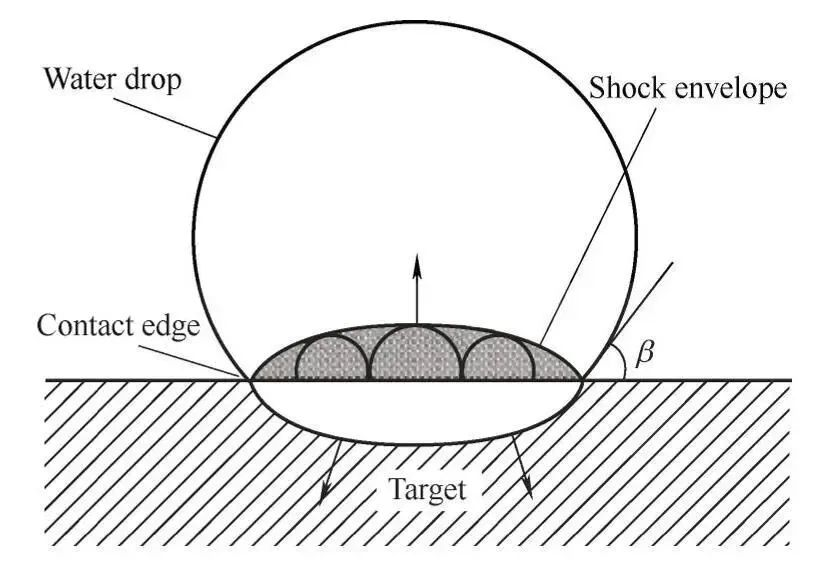

As shown in Figure 5, at the moment of high-speed impact with the solid surface, the droplet rapidly expands to form a compressed liquid region, generating instantaneous high pressure. The impact surface undergoes local plastic deformation, forming a large number of small depressions, or tensile failure leading to surface and subsurface damage.

(2) Stress wave

High pressure compression of liquids generates compression and shear stress waves that propagate through solids, interact with the internal structure of materials, reach the boundary of microstructures, reflect and continue to act, creating a tensile load area that can cause further damage.

(3) High speed transverse jet

Compressed liquid flows radially along the liquid-solid edge, generating a high-speed transverse jet that is ten times faster than the impact velocity. It interacts with irregular solid surfaces, generating shear stress that leads to local deformation and sub micron level defects. Agglomerated micro defects form erosion pits.

Figure 5: The moment when a droplet collides with a solid surface

(4) Hydraulic penetration

Droplets hitting solid surfaces create erosion pits or microcracks, leading to stress concentration. Under sustained action, cracks continue to propagate from the sidewalls and bottom of the erosion pits, causing submicron sized cracks to expand to a few millimeters. This further changes the geometric shape of the solid surface and intensifies the impact, accelerating crack propagation again until macroscopic failure occurs.

However, due to the subjective assumptions of existing droplet erosion mechanism models that do not fully match the actual situation, research is mainly limited to simplifying conditions and laboratory testing of samples, and the proposed model lacks validation.

Therefore, there is currently no complete theoretical system or erosion model that can be applied to actual droplet erosion situations.

Aircraft engine hot end components

The hot end components of aircraft engines include combustion chambers, high-pressure turbines, exhaust nozzles, etc., mainly composed of single crystal nickel based high-temperature alloys, cobalt based high-temperature alloys, ceramic based composite materials, and thermal barrier coatings. They are subjected to complex erosion damage in harsh service environments, mainly high-temperature particle erosion and high-temperature multiphase flow erosion. In order to improve efficiency and thrust to weight ratio, the operating temperature of aircraft engines has been rapidly increasing at a rate of nearly 15K per year since 1960.

The maximum operating temperature of single crystal nickel based and cobalt based high-temperature alloys used in the hot end components of the engine is limited to around 1100 ℃. In order to improve the fuel efficiency of aircraft engines, achieve higher operating temperatures, improve performance, and extend the life of engine components, there are strict requirements for the materials used in the high-temperature areas of the engine.

To further improve the high-temperature resistance of hot end components such as combustion chambers and turbine blades in aircraft engines, ceramic matrix composites (CMC) are a feasible alternative to high-temperature alloys, and SiC/SiC components have been applied to the hot end components of aircraft engines, combustion chambers, and turbines (CFMLEAP engines).

CFM company uses Al2O3/Al2O3 composite materials in the exhaust pipes and nozzles of LEAP-X engines.

IHI Corporation in Japan is vigorously developing CMC components for aircraft engines to achieve performance improvements and weight reduction. At the same time, in order to achieve high energy conversion efficiency of aircraft engines, turbines require extremely high inlet temperatures, and the application of thermal barrier coatings (TBC) effectively meets this demand.

PADURE et al. found that using a coating with a thickness of 100-500 μ m in conjunction with an internal cooling system can significantly reduce the surface temperature of hot end components by 100-300 ℃. This enables modern engines to operate at service temperatures higher than the melting temperature of high-temperature alloys (~1300 ° C), reducing cooling air flow and improving gas temperature, engine thrust, and efficiency while enhancing overall service life.

The currently widely used thermal barrier coatings are mainly electron beam physical vapor deposition (EB-PVD) and atmospheric plasma spraying (APS). Their geometric structures include a heat-resistant ceramic surface layer (TC), a bonding layer (BC), and a high-temperature alloy substrate. Among them, the thermal barrier coatings prepared by EB-PVD technology have better erosion resistance.

01 High temperature particle erosion

During service, the hot end components of an aircraft engine are subjected to surface erosion from high-speed, hard particles trapped in the intake airflow, similar to the particle erosion behavior of cold end components.

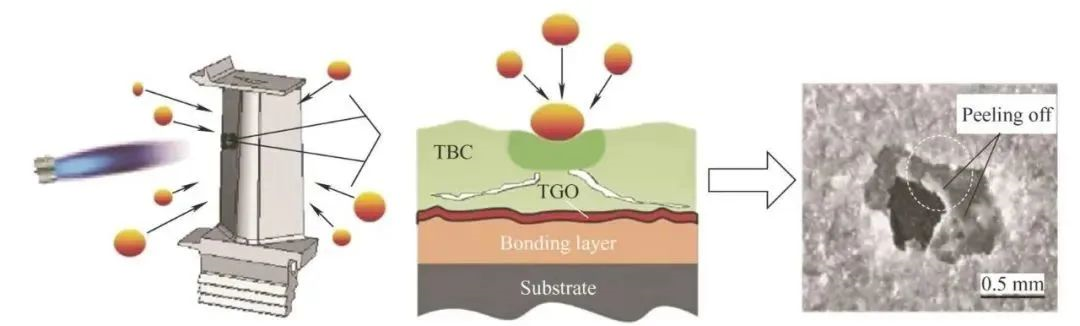

In addition, particles at high temperatures also cause severe erosion damage to thermal barrier coatings. As shown in Figure 6, the erosion damage of thermal barrier coatings by high-temperature particles mainly refers to the hard particles inhaled by the engine during operation, particles formed by erosion of the engine combustion chamber walls, turbine blades, and carbon particles generated during the engine combustion process, repeatedly impacting the thermal barrier coating under high-temperature and high-speed airflow, causing the ceramic layer to compact and resulting in thickness changes, stress concentration, crack initiation, and even coating peeling.

FLECK, WELLMAN, CERNUSCHI, DREXLER and others have studied and summarized the damage forms of high-temperature particle impact thermal barrier coatings as follows.

(1) Foreign particle damage

At high speeds, large-sized inhaled particles collide with the surface of EB-PVD thermal barrier coatings, causing local plastic deformation and densification around the contact area. The microstructure in the deformation zone twists, fractures, and connects into crack bands, which propagate to the interface of thermally grown oxide (TGO) and cause internal delamination of the thermal barrier coating, resulting in large-scale peeling.

(2) Near surface cracking

The low-speed small particles generated by the engine's own operation collide with the EB-PVD thermal barrier coating near the surface area, causing elastic-plastic deformation and rupture. The high-speed large particle impact causes the coating surface to collapse or undergo non-uniform cyclic plastic deformation, resulting in erosion pits, which in turn cause coating peeling or local compaction.

(3) Flaky peeling

Solid particles collide with APS thermal barrier coatings and create indentations on the surface, forming cracks along the microstructure boundaries and propagating until adjacent holes and parallel cracks are connected in series within the coating, causing the coating to peel off in patches.

(4) CMAS erosion failure

The erosion particles composed of calcium magnesium aluminum silicate (CMAS) deposit on the surface of the thermal barrier coating, melt at the combustion chamber temperature, and flow into the cracks and micropores inside the coating. During the solidification process, phase transition volume expansion occurs, causing the coating to increase shear stress and peel off, or infiltrate into the bottom of the coating to cause delamination or cracking.

Unlike the impact damage caused by particle erosion in cold end components, erosion behavior in hot end high-temperature environments is often accompanied by a series of physicochemical reactions such as adhesion, melting, melt infiltration, and solidification. After mechanical erosion damage, the erosion particles and products react to cause secondary or sustained damage to the components.

Figure 6 Erosion damage and peeling of TBCs

02 High temperature multiphase flow erosion

During the operation of an aircraft engine, abnormal solid particles are generated when the combustion chamber is ablated or rich in oil is burned. These particles form high-temperature condensed phase particles with combustion products such as CO2, water vapor, and small diameter soot particles. They exist in various states (solid/liquid/gas) or complex heterogeneous states and rapidly evolve in a high-temperature and high-speed carrier environment. During the transient process, they impact the combustion chamber, turbine blades, or tailpipe inner wall at high speed, causing erosion of the insulation material, elastic and plastic deformation, particle rebound, severe mechanical and thermal loads, and even slip and shear rupture along the inner wall surface, resulting in additional power loss of the engine.

At the same time, under high temperature, particles undergo phase transition, softening, deformation, sintering, and adhering to the combustion chamber liner, fuel nozzle, high-pressure nozzle guide vanes, and turbine surface to block cooling holes (as shown in Figure 7), or change the internal aerodynamic conditions of the engine, react chemically with thermal barrier coatings, causing compressor surge and even outlet temperature exceeding the allowable temperature of the engine, resulting in engine shutdown.

However, due to the difficulty and high cost of directly characterizing the interaction behavior between high-temperature multiphase fluids and components and determining their transient characteristics, as well as the need to include a large number of interrelated and sometimes unknown parameters in the establishment of data models, related research mainly focuses on developing simplified models based on experience and simple physical experiments. So far, there have been few reports on universal models that fully consider the interaction of multiphase fluids in different states.

Figure 7 Aging behavior inside the engine

2、 Anti erosion coating system for aircraft engines

The main form of erosion damage in aircraft engines is solid particle erosion, and the protection against solid particle erosion is also a current research focus.

In the 20th century, Urban et al. proposed the use of surface protection to mitigate the impact of solid particle erosion. At present, anti erosion coatings have shown good results in solid particle erosion protection, and their application in engine cold and hot end components also differs significantly.

The main anti erosion coating system for cold end components

So far, scholars from various countries have conducted decades of research on erosion resistant coatings for aircraft engines.

ALQALLAF et al. summarized the development of erosion resistant coatings as follows: the first generation of coatings were single-layer nitride coatings, but related studies found that the coatings did not achieve the expected protective effect due to their high internal stress and low toughness;

The second generation coating is composed of a multi-layer structure of metal/ceramic, and the cracks generated by solid particle erosion on the surface layer are blocked by a tough internal layer, which can better regulate internal stress.

On this basis, nano multilayer erosion resistant coatings have been developed, and related studies have shown that their performance is superior to traditional second-generation multilayer coatings. The improvement in performance is due to the presence of ultrafine grains (≤ 10nm) in the nano coating, which greatly increases the number of interfaces between materials with different shear moduli, suppresses columnar crystal growth, and consumes erosion particle kinetic energy. In addition, the sharp interlayer boundaries at the nano level can prevent crack initiation and unstable propagation.

01Single layer ceramic coating

Due to strict regulatory requirements in the aerospace industry, relevant reports mention that the coatings used for erosion protection in aircraft engines are mainly titanium nitride (TiN) coatings, which can extend the service life of compressor components by 2-3 times. According to statistics, erosion resistant coatings have been successfully used in dozens of types of aircraft engines in European and American countries.

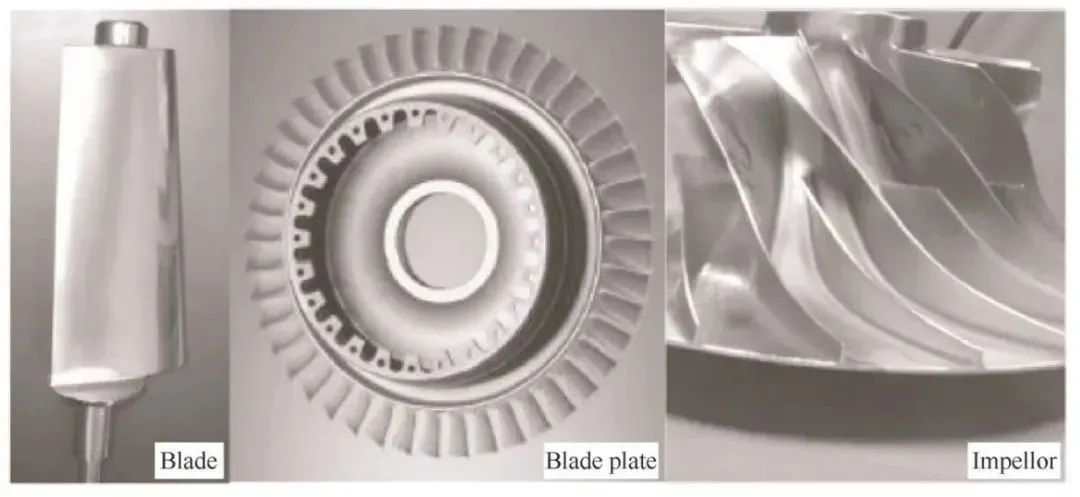

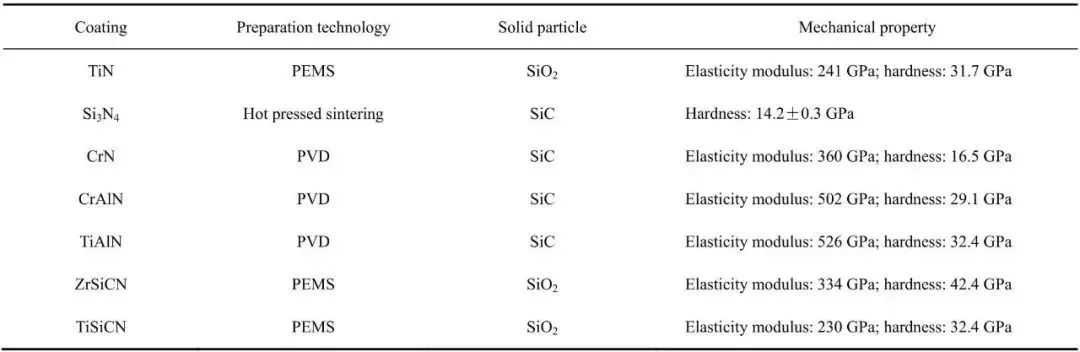

The specific physical objects of TiN coated blades, discs, and impellers are shown in Figure 8. In the subsequent development, multiple systems of single-layer ceramic coatings have emerged, mainly including transition metal/non-metal nitrides, nitrogen aluminides, carbon nitrides, and carbide ceramics. Some coating parameters are shown in Table 1.

Figure 8 Physical picture of components used in coated compressors

Table 1: Parameters related to nitride ceramic coatings

Sun Zhiping et al. studied TiN/Ti coatings and TiN/ZrN coatings and analyzed the effects of hot corrosion and salt spray corrosion on the erosion behavior of nitride coatings.

Research has found that coatings form pitting corrosion pits during salt spray corrosion, and loose oxides and corrosion products are formed during hot corrosion. At the same time, the interlayer thermal stress generated weakens the adhesion of the coating, making it easier for the coating to peel off during erosion.

Tian Tian et al. used vacuum cathodic arc deposition technology to deposit CrN and CrAlN coatings on TC11 titanium alloy, and studied the influence of coating microstructure on erosion resistance.

The results showed that the erosion rate of the coated sample was only 1/8 of that of the titanium alloy substrate at 30 ° and only 1/3 at 90 °. In addition, the morphology of crack propagation at the erosion pit was analyzed, and it was found that under high erosion angle conditions, the failure mechanism of the coating was brittle fracture.

WEI et al. used plasma enhanced magnetron sputtering (PEMS) technology to deposit nitride (ZrN, CrN, and TiN) and carbon nitride (ZrSiCN and TiSiCN) coatings on the surface of Ti6Al4V substrate. According to observations, TiSiCN has the best erosion resistance, nearly 25 times higher than the substrate and 5-10 times higher than all other nitrides.

In the early stages of research, relevant studies generally adopted the method of designing high hardness coatings to enhance the erosion resistance of coatings. However, single-layer ceramic coatings have high internal stress, brittleness, and low fracture toughness, making it difficult to meet the performance requirements of the design. Meanwhile, single-layer ceramic coatings generally have a columnar crystal structure with a certain number of gaps, which affects the overall erosion resistance of the coating.

Therefore, multi-layer/nano multi-layer ceramic coatings with good toughness matching have become the focus of research.

02 Multilayer/Nano Multilayer Ceramic Coating

Based on issues such as high strain rate impact, instantaneous high-speed high stress friction, and complex component layout during the service of aircraft engine components, the strength and toughness matching of erosion resistant coatings and microstructure design requirements are high. Related studies have found that brittle materials (such as ceramics) have the highest erosion rate at or near 90 ° incidence angles, while plastic materials (such as metals) have the highest value at lower angles close to 30 °.

With the development of nanotechnology and diversification, the application of nano multilayer superlattices and nano composites has promoted a good match between hard and tough coatings. Based on this, some scholars have proposed that the alternating design of hard and plastic layers is suitable for erosion resistant coatings.

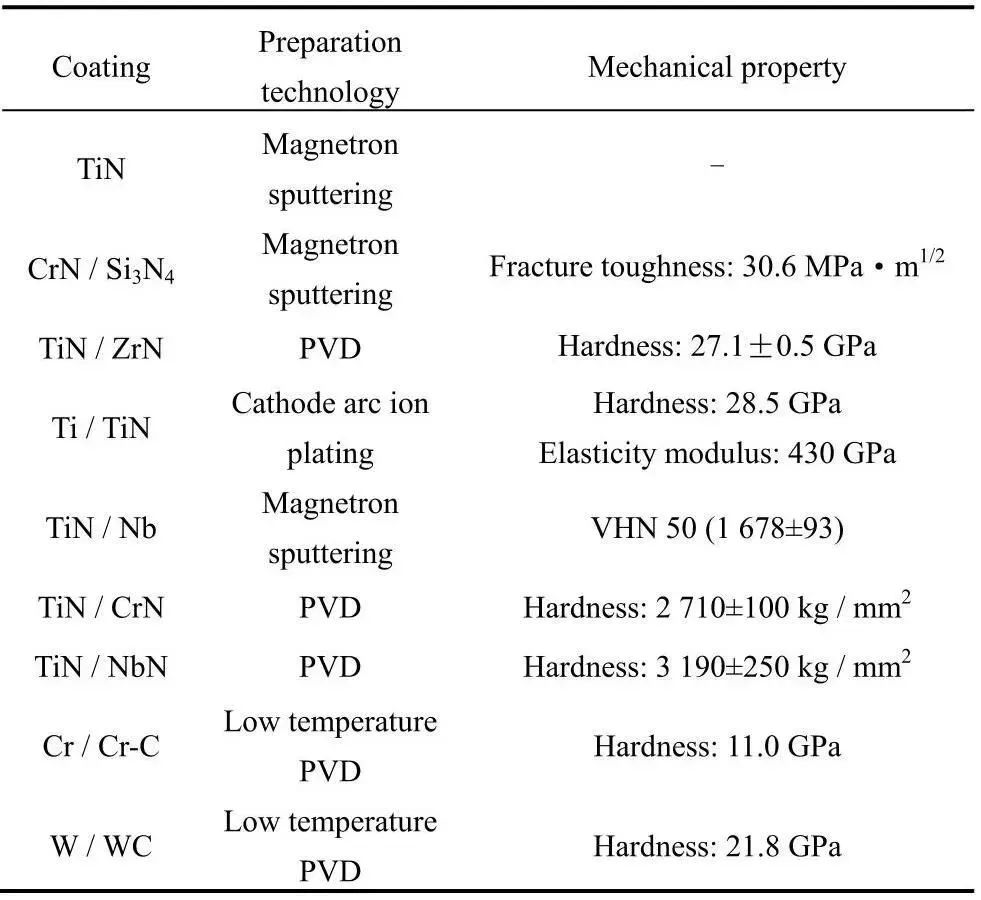

At present, multilayer/nano multilayer ceramic coatings mainly include transition metal nitride/nitride (MeN/MeN), nitride/metal (MeN/Me), and carbide (MeC) ceramic systems.

Due to the ability of multi-layer interfaces to suppress columnar crystal growth, dissipate erosion particle kinetic energy, release stress, coordinate deformation, and exhibit viscous damping effects on dislocations, cracks are prone to deflect at the interface of multi-layer coatings, avoiding stress concentration and crack propagation inside the coating. Nanostructure leads to passivation of crack tips, and other comprehensive effects, the erosion resistance of multi-layer/nano multi-layer ceramic coatings is generally excellent. The relevant parameters of some multilayer/nano multilayer ceramic structural materials are shown in Table 2.

Table 2 Relevant parameters of multi-layer ceramic structural materials

In the 1980s, companies such as MDS-PRAD and GE prepared ER-7 coatings using physical vapor deposition technology and applied them to the engines of US military helicopters and transport planes.

The coating is a multi-layered structure with alternating soft and hard layers, mainly composed of titanium nitride. The outermost layer is a hard and dense nickel based metal, which has strong resistance to multi angle impact.

The results of small-scale field trials of the engine show that the average installation and use time of the engine in desert environments has been extended from 113 hours to 374 hours, an increase of nearly 3.3 times. The ER-7 coating has good solid particle erosion protection ability.

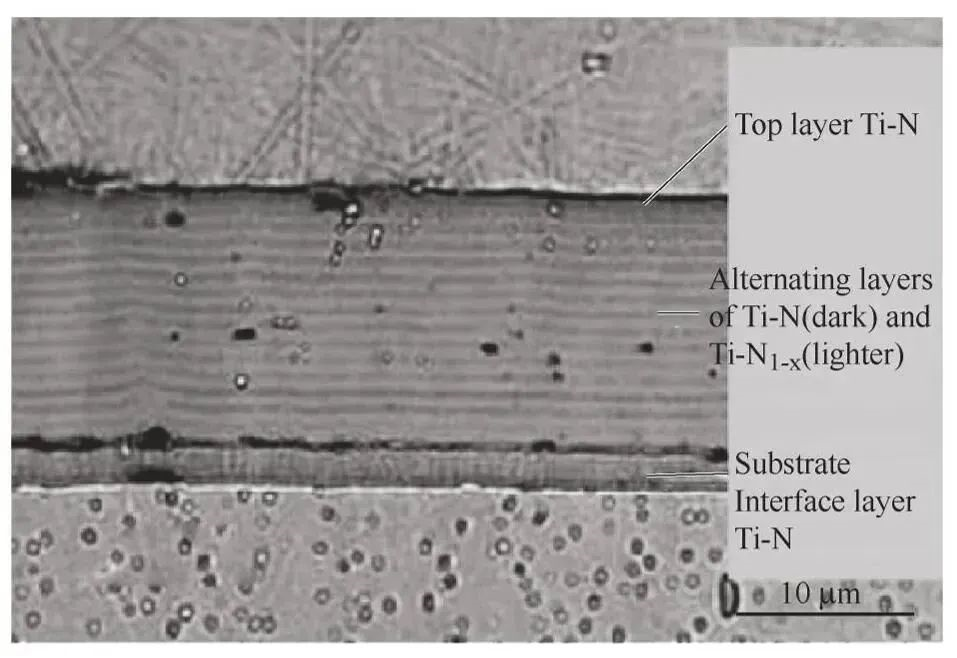

FEUERSTEIN et al. reported on the development of TiN/TiN1-x nano multilayer film "24kTypeII" for erosion protection of compressor blades by Praxair Surface Technologies ™”, The erosion test of Al2O3, large particle silica sand, and small particle sand has shown good results. Figure 9 shows the structural design of the nano multilayer film.

BONU et al. developed Ti/TiN nano layer multi-layer anti erosion coating using sputtering technology, and tested it at 400 ℃ according to ASTM G76 standard. The erosion performance of the coating reached 15 times that of Ti6Al4V substrate.

In order to ensure that carbon fiber reinforced polymer (CFRP) components subjected to erosion wear have sufficient service life, MAURER et al. prepared metal Ti, Al, Cr, and multi-layer Ti/TiN coatings on the surface of CFER using PVD technology and conducted erosion tests. It was found that the multi-layer Ti/TiN coating provided the best protective effect.

Figure 9 TiN/TiN1-x nano multilayer film structure

03 Other coating systems

Compared with metal based materials, the insufficient erosion resistance of polymer based composites (PMC) is a key factor affecting their application in aircraft engines.

PMC has the advantages of high strength, strong design, and fatigue resistance. Compared with metal materials, PMC can reduce component weight by 20% to 30%. When applied to propulsion systems, it can reduce weight, improve strength, and reduce fuel consumption. Using PMC instead of traditional metal structural materials in the design of fan blades, stationary blades, guide vanes, and casings has become a trend in advanced aircraft engine design.

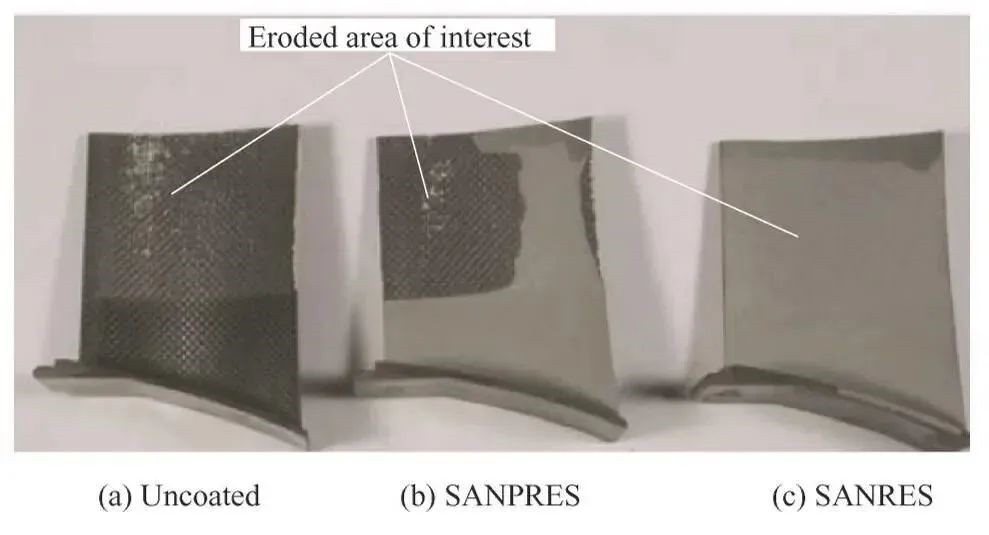

NASA Glenn Research Center and Rolls Royce have developed erosion resistant coatings SANPRESS and SANRES to extend the lifespan of high-temperature PMC components, and tested them on the bypass blades of the AE3007 engine, as shown in Figure 10. These two coatings have achieved improvements of 2 times and 4.8 times in reducing erosion depth and volume loss, respectively.

Figure 10 Appearance of the trailing edge of the blade after erosion test

DRENSKY et al. simulated the particle impact under the flow conditions of a turbofan in a high-temperature erosion wind tunnel (260 ℃, 152.4m/s), and tested the erosion effect of gravel with particle sizes of 10 μ m and 100 μ m on a polyether ketone (PEEK) matrix and a unidirectional (AS4) carbon fiber composite coating. The results showed a peak erosion rate at a 45 ° impact angle, which increased with temperature and particle impact velocity.

CUI et al. deposited multiple layers of coatings on carbon fiber reinforced bismaleimide polymer composites using explosive spraying. The coatings consisted of a polymer aluminum mixed transition layer, a pure aluminum bonding layer, and a WC-17Co top layer. Solid particle erosion tests were conducted on the coated and uncoated PMCs at 25 ° C and 250 ° C. The results showed that the volume loss of the coated PMC was less than 1/10 of that of the uncoated PMC, and the coating effectively prevented PMC from being eroded.

Main erosion resistant coating system for hot end components

01 Environmental barrier coating

In order to maintain long-term stability during the service of aircraft engines, environmental barrier coatings (EBC) have become an indispensable protective layer on ceramic matrix composite (CMC) components.

Compared with nickel based high-temperature alloys, CMC has better durability and lower material density at high temperatures. However, due to factors such as particle erosion, mechanical impact, and thermal shock in application scenarios, the inherent brittleness of ceramic matrix composites can lead to high erosion wear rates, thereby reducing their service life and safety reliability.

Therefore, in order to achieve applications under harsh conditions such as high temperature, high speed, and heavy load, relevant scholars have conducted toughening research on it.

Fan Chaoyang et al. studied the solid particle erosion behavior of carbon fiber reinforced Al2O3 composite materials using corundum powder as a medium. Thanks to the reinforcing and toughening effect of carbon fibers, C/Al2O3 composite materials do not undergo brittle fracture during erosion and wear. Even if the matrix density of the composite material is low, the safety of use is still better than that of single Al2O3 ceramics.

However, FABIAN et al. studied the erosion resistance of nano mullite whiskers and zirconia toughened alumina ceramic composites and found that the reinforcement and toughening of ceramic whiskers had almost no positive effect on the erosion resistance of ceramics at room temperature, and even had potential hazards.

Therefore, using EBC for erosion protection of CMC is more stable and reliable, and has great application value.

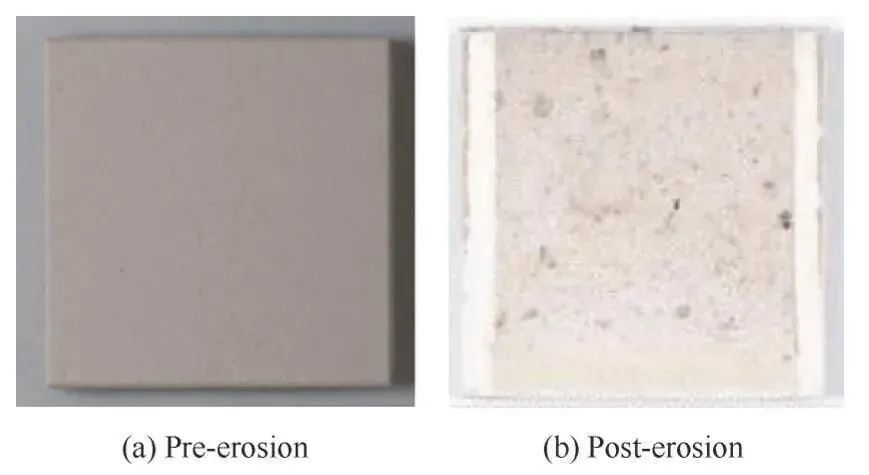

OKITA et al. conducted high-temperature erosion wind tunnel tests on the CMC surface of turbine blades using environmental barrier coating EBC on SiO2 particles. The test parameters were consistent with the aerodynamic and thermal conditions as well as erosion characteristics of typical turbine wing components operating in an aircraft engine particle load environment. In later work, the influence of high-temperature multiphase flow was analyzed, as shown in Figure 11.

The results showed that CMC+EBC exhibited typical brittle erosion behavior, and the erosion rate reached its maximum at the highest impact angle.

Presby et al. investigated the erosion behavior of ytterbium disilicate (Yb2Si2O7) EBC in a combustion environment at 1200 ℃ with Al2O3 as the medium, and found that EBC exhibited brittle fracture damage behavior.

AHLBORG et al. studied the stability of yttrium disilicate EBC doped with rare earth oxides HfO2 and ZrO2 in contact with CMAS at high temperatures. They found that CMAS preferentially penetrates the sample at grain boundaries and dissolves the EBC material to form low melting point grain boundary bands. Lower rare earth oxide doping concentrations have better resistance to CMAS, but with increasing doping concentration, the stability of EBC deteriorates.

Figure 11 Appearance of typical CMC+EBC specimens before and after testing

For engines operating in complex and harsh environments, EBC needs to have high-temperature stability, sealing performance, thermal cycling/impact resistance, erosion resistance, etc. Erosion is one of the key factors affecting the service life of EBC. However, currently, research on the erosion behavior of hot end components mainly focuses on thermal barrier coatings, and optimizing the erosion resistance of EBC requires a lot of research.

02 Modified Thermal Barrier Coating

During the service of aircraft engines, the high-temperature gas generated in the combustion chamber and the high-temperature particles in the airflow are prone to erosion and cracking on the surface. The thermal barrier coatings used in corresponding components need to have high operating temperatures and erosion resistance, and targeted modification design has become a research hotspot.

WANG et al. reported the erosion behavior of 7YSZ thermal barrier coatings modified by laser remelting. The study found that laser remelting can eliminate the layered structure and most of the pores on the top layer of the thermal barrier coating, forming a uniform and dense ceramic layer. The mass loss of laser remelted samples at different erosion angles is 35% to 82% of that of the corresponding ion sprayed samples, effectively improving the erosion resistance of the thermal barrier coating.

TIAN et al. prepared YSZ coatings modified with AlBOw and BNw whiskers by plasma spraying. The addition of whiskers improved the density and toughness of the coatings, reduced the degree of crack connection, and prevented crack propagation during erosion. The erosion rate was reduced by 8.17% and 13.94% compared to YSZ coatings, respectively.

RAMANUJAM et al. used the method of ductile phase modified thermal barrier coating to effectively improve the erosion resistance of the coating by adding some ductile CoNiCrAlY powder to YSZ. Combined with data models, it was found that the added ductile metal absorbed kinetic energy under particle impact, underwent plastic deformation, and slowed down the erosion damage of the coating by hindering crack propagation.

In terms of CMAS damage, JULIE et al. studied the damage effect of molten volcanic ash on Gd2Zr2O7 (GZO) and YSZ+Al+Ti thermal barrier coatings. Compared with the damage behavior of conventional 7YSZ thermal barrier coatings, the two modified coatings avoided the flow of molten CMAS into the gaps of the thermal barrier coatings by forming a stable and impermeable crystalline layer, and both showed good CMAS resistance.

ZHANG et al. studied the erosion resistance of EB-PVD7YSZ thermal barrier coatings modified with Al. The results showed that during vacuum heat treatment, Al reacted in situ with ZrO2 to form a dense Al2O3 coating on the top of TBC, which hindered the initiation of cracks and the penetration of CMAS on the coating surface during solid particle impact, and played a significant role in erosion resistance.

WANG et al. prepared Pt thin films on EB-PVDYSZ coatings by electroplating, and found that dense Pt films with moisture resistance and non permeability can effectively prevent CMAS damage.

03 Exploration of Other Coating Systems

The development of erosion resistant coatings for high-temperature applications plays a crucial role in improving the service life of engine materials and enhancing the overall performance of aircraft engines. In addition to the erosion resistance modification of thermal barrier coatings with practical application environments, relevant scholars have also explored coating systems with high temperature environment erosion resistance application prospects.

BARSOUM refers to ternary transition metal carbide or nitride ceramic materials with special structures and metalloid properties as the "Mn+1AXn phase". In the special nano layered structure of the MAX phase, the MA layer with metallic properties alternates with the MX layer with covalent properties, exhibiting excellent resistance to thermal shock, high-temperature oxidation, and erosion.

NAVEED et al. prepared Ti2AlCMAX phase coating on the surface of Ti-6242 (6Al-2Sn-4Zr-2Mn) alloy, a good candidate material for aircraft engine rotating components, by magnetron sputtering and conducted high-speed particle erosion tests. The results showed that the material's erosion resistance was greatly improved.

MEN et al. studied the erosion behavior of Ni based alloy coatings under high-temperature and high-pressure airflow caused by propellant combustion. They found that high-temperature and high-pressure airflow led to material peeling and the formation of erosion pits on the micro scale of the coating surface, resulting in surface cracking and the formation of transverse macroscopic cracks, which continued to expand during the counter erosion process. The erosion caused by high-speed airflow also leads to microscale material delamination and the formation of erosion pits on the surface of alloy coatings.

With the development of high-performance and long-life new aircraft engines, the erosion behavior of coatings in high-temperature environments has become increasingly complex. Conducting research on new high-temperature erosion protective coatings and strengthening the study of microstructure evolution behavior and damage mechanisms during coating service are of great significance for improving the comprehensive performance and service life of aircraft engines.

3、 Coating erosion resistance test system

The erosion test system is the most intuitive and effective measure to evaluate the effectiveness of coating design, controllability of preparation technology, stability, and coating erosion resistance. The completeness and effectiveness of the test system directly affect the protective ability of the coating in practical use. Currently, multiple research institutions both domestically and internationally are conducting research in the field of erosion resistance testing and assessment.

01 Evaluation Criteria

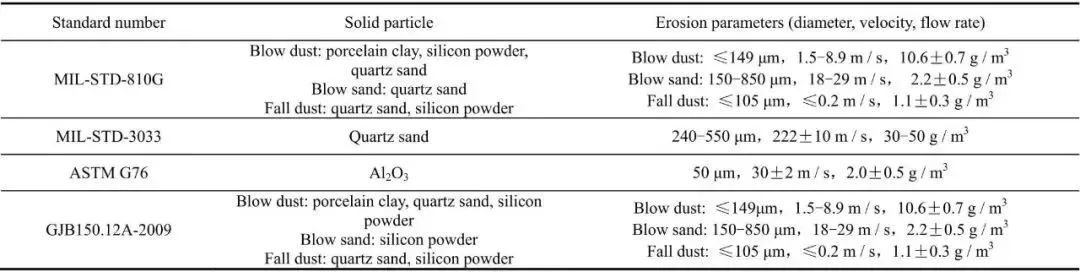

At present, the evaluation standards for erosion testing at home and abroad mainly focus on solid particle erosion, including MIL-STD-810G (US Military Environmental Testing Standard), which is mainly used to evaluate the adaptability of equipment that may be exposed to dry sand blowing, dust blowing, or dust reduction conditions;

MIL-STD-3033 (Solid Particle Erosion Test Standard for Rotor Blade Protective Materials) mainly provides a standard for testing the sand erosion (particle erosion) resistance of commonly used materials for US aircraft engine blades, including synthetic rubber, reinforced plastics and composite materials, metals, ceramics, and coatings;

ASTM G76 (Standard Test Method for Solid Particle Impact Corrosion Test Using Gas Jet), applicable to specimens, blocks, or coated blocks;

GJB150.12A-2009 (Military Equipment Laboratory Environmental Test Method - Sand Dust Test) is applicable for evaluating mechanical devices that may be exposed and dry under blowing sand, blowing dust, or reducing dust conditions. Some parameter comparisons are shown in Table 3.

Table 3 Comparison of Standard Parameters for Solid Particle Erosion Test

02 Testing device

At present, various research units mainly conduct coating erosion behavior testing through independently developed experimental simulation systems, such as special wind tunnel devices, gas spray gun devices, or industrial heating devices. At a certain temperature, one or more hard particles are sprayed onto the coating surface at a certain angle and velocity to study the erosion damage mechanism of the coating.

·The NASA Research Center in the United States has developed a high-speed combustion chamber test bench with hard particle erosion capability, which simulates the erosion environment of turbine engine service in the laboratory to evaluate the erosion behavior of ceramic coatings and thermal barrier coatings.

·The Federal Armed Forces University of Munich in Germany integrated a jet erosion test bench with an arc heated plasma wind tunnel to study the erosion behavior of nickel based Mar-M247 and INCO718 high-temperature alloy substrates and thermal barrier coatings in Al2O3 particles as a medium at 800-1350 ℃.

·The Multiscale Materials Characterization Laboratory at the University of Cincinnati constructed a high-temperature erosion wind tunnel to simulate the erosion behavior of composite material coatings under high-temperature and high-speed particle impact of turbofan service conditions.

·Harbin Engineering University Jin Guo and others have independently developed and obtained national invention patent authorization for a multi extreme working condition erosion test device suitable for multi field coupling conditions and a multi medium corrosion erosion coupling test device under ocean temperature simulation environment. They have completed the study of erosion behavior of anti erosion coating materials for compressor shafts and high-temperature turbines under simulated ocean and land conditions in coupled environments such as room temperature, high temperature, and salt spray.

·The Air Force Equipment Research Institute has developed an integrated sand and dust testing system to solve technical difficulties such as optimizing sand addition methods, temperature regulation, measuring and controlling sand/dust concentrations, and integrating sand and dust blowing. This provides a scientific testing method for assessing the environmental adaptability and product reliability of equipment.

·Xiangtan University has developed a gas spray gun that can simulate high-temperature thermal shock of thermal barrier coatings, and designed a particle feeding system with controllable speed and flow rate in the gun. By regulating temperature and particle flow rate, the simulation of the erosion service environment of thermal barrier coatings at room temperature and various temperatures can be achieved.

·Beijing Institute of Aeronautical Materials has built a solid particle aerated erosion test device based on the ASTMG76-04 standard, and has conducted in-depth research on solid particle erosion of thermal barrier coatings and nitride coatings.

·Northwestern Polytechnical University has developed a self-made pneumatic erosion testing machine with years of research in marine conditions and high-temperature high-speed erosion.

·The GW/CS-MS erosion testing machine developed by Beijing Armored Forces Engineering College based on the ASTMG76-95 standard.

·The gas-solid two-phase flow erosion wear tester made by the Institute of Metals, Chinese Academy of Sciences, has carried out long-term research in the erosion field of cermet coatings and polymer matrix composites.

4、 Conclusion and outlook

By analyzing the erosion damage forms and research progress of protective coatings on the cold and hot end components of aircraft engines, this paper summarizes and summarizes the application examples and testing systems of existing anti erosion protective coating systems.

Based on existing reports, the current developments in related fields can be summarized as follows:

(1) The research on erosion damage of aircraft engines mainly focuses on the hard particle erosion of compressor blades and other components. A relatively complete damage mechanism and coating protection mechanism have been explored, and a series of testing evaluation standards and testing device systems have been established. However, there is relatively little research on erosion damage of liquid droplet erosion, CMC and PMC material components, and the corresponding damage mechanism and coating protection mechanism lack a complete theoretical system support.

(2) Significant achievements have been made in the field of erosion resistant coating technology, and some coatings have been applied to various engines and achieved good protective effects. However, most coating systems are limited to laboratory level hard particle erosion experiments, and there is little research on the service behavior of coatings under coupling effects such as high speed, high temperature, high stress, and complex structures in real service conditions.

(3) At present, certain evaluation criteria have been established for the coupled erosion behavior of multiphase flow under multiple working conditions, and a testing device and evaluation method for the protection and damage behavior of coatings under complex multi medium erosion have been successfully constructed. However, the thermal coupled erosion testing system for long-term high temperature in marine and land environments still needs to be developed.

In the future, building a comprehensive mechanism and testing evaluation system for erosion damage and coating protection will enable the comprehensive application of anti erosion coatings in the aerospace industry, providing guarantees for the flight life, reliability, and safety performance of domestic engines in service environments. A large amount of basic research and technical verification are still needed.