Hydrogen energy is a new trend in global energy transformation and development, and an important component of the modern energy system, which will have a profound impact on the prospects of China's energy development. The commercialization pace of the global hydrogen energy industry is constantly accelerating, and energy giants from various countries are competing to layout the hydrogen energy industry.

Huatian Aviation Power aims at the development direction of the global hydrogen energy industry, conducts in-depth research on the technological development and practical application of hydrogen gas turbines, and compiles this article in order to provide reliable technical support and practical samples for the widespread application of gas turbines in the hydrogen energy field.

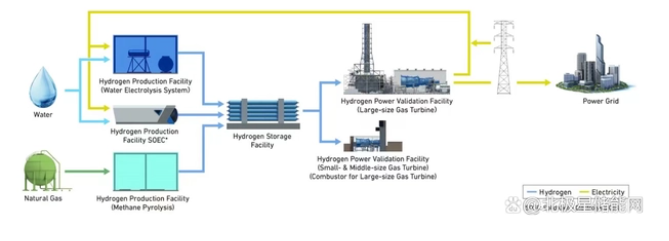

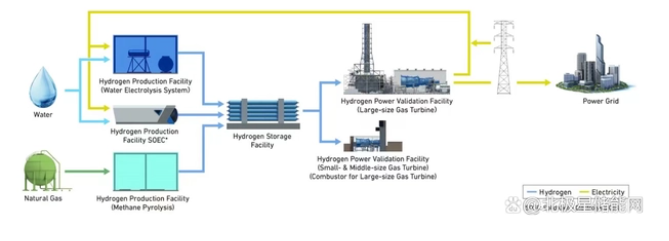

Mitsubishi Electric is constructing the "Takasago Hydrogen Industrial Park" hydrogen energy demonstration facility at Takasago Machinery Plant by adding hydrogen production and storage equipment to existing verification facilities,To validate the inherent logic of the hydrogen energy value chain from production to power generation, in order to support the commercialization of hydrogen gas turbines by 2025.We plan to achieve zero carbon emissions while maintaining low NOx levels by using heavy-duty JAC gas turbines and small to medium-sized H-25 gas turbines.

The High Sand Hydrogen Gas Turbine Zero Carbon Industrial Park is located near the world-renowned Mitsubishi Electric T-Point2 Combined Cycle Power Plant validation facility, which will beThe world's first demonstration center to validate hydrogen related technologies from hydrogen production to hydrogen power generation,We are currently conducting various preparatory tests and demonstrations, including hydrogen production and storage, as well as hydrogen fuel preparation for gas turbines,Commercialization of 100% pure hydrogen combustion for gas turbines will be achieved by 2025.

The demonstration of the High Sand Hydrogen Gas Turbine Zero Carbon Industrial Park is a comprehensive system that covers various aspects of hydrogen gas turbine related technologies. From developing, demonstrating, and validating key components of hydrogen gas turbines such as combustion chambers, to designing, producing, and testing actual machines in manufacturing plants. From the verification and testing of all hydrogen related components in the basic design stage, to the calculation of the entire air system and temperature field in the detailed design stage, the aerodynamic performance calculation of the combustion chamber and turbine blades, as well as the extensive process and engineering design changes involved in the final assembly and testing. While refreshing the technology, a design workflow for hydrogen gas turbines has also been created to ensure faster development cycles, more definite products, and successful commercialization of the units.

The entire verification and demonstration content is divided into two main parts,Conduct a 30% hydrogen blending combustion test on the 566MW JAC heavy-duty gas turbine undergoing long-term testing and assessmentAnd gradually increase the amount of hydrogen doping on this basis.Conduct 100% pure hydrogen combustion tests using a 40MW H-25 small and medium-sized gas turbine.

As an important component of its energy transformation strategy, Mitsubishi Electric is building a complete hydrogen energy value chain from production to use by further integrating existing energy facilities with hydrogen related products. And on this basis, establish a 'hydrogen energy industry ecosystem' to lay the foundation for sustainable social development, and accelerate its ecosystem through verificationCommercialization.