Working process, classification, characteristics, and key technologies of gas turbines

1、 Introduction to Gas Turbine

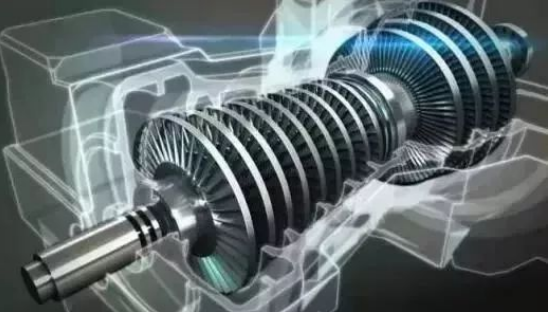

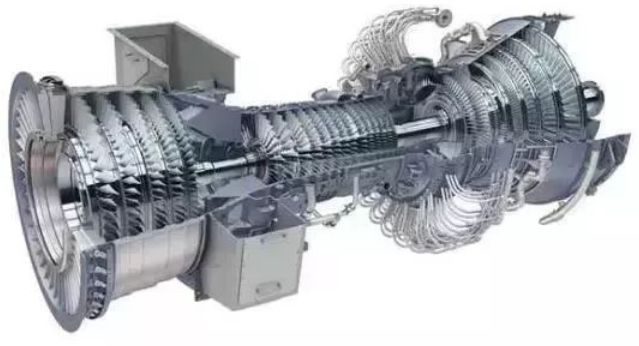

A gas turbine is a rotary power machine that uses continuously flowing gas as the working fluid to convert thermal energy into mechanical work. A gas turbine cycle consisting only of three major components: the compressor, the combustion chamber, and the gas turbine, is commonly referred to as a simple cycle. Most gas turbines adopt a simple cycle scheme. Because its structure is the simplest and best reflects a series of advantages unique to gas turbines, such as small size, light weight, and fast start-up.

Usually in gas turbines, the compressor is driven by the expansion work of the gas turbine, and it is the load of the turbine. In a simple cycle, about 1/2 to 2/3 of the mechanical work generated by the turbine is used to drive the compressor, while the remaining 1/3 of the mechanical work is used to drive the generator. When starting a gas turbine, external power is first required. Generally, the starter drives the compressor until the mechanical work generated by the gas turbine exceeds the mechanical work consumed by the compressor. When the external starter trips, the gas turbine can operate independently.

2、 The working process of gas turbine

The working process of a gas turbine is that the compressor continuously sucks in air from the atmosphere and compresses it; The compressed air enters the combustion chamber, mixes with the injected fuel, and burns to become high-temperature gas, which then flows into the gas turbine to expand and do work, pushing the turbine impeller to rotate together with the compressor impeller; The work capacity of the heated high-temperature gas is significantly improved, so the gas turbine not only drives the compressor, but also has surplus work as the output mechanical work of the gas turbine.

The initial temperature of gas and the compression ratio of the compressor are the two main factors affecting the efficiency of gas turbines. Raising the initial temperature of gas and correspondingly increasing the compression ratio can significantly improve the efficiency of gas turbines. In the late 1970s, the compression ratio reached a maximum of 31, and the initial temperature of gas for industrial and marine gas turbines reached around 1200 ℃, while that for aviation gas turbines exceeded 1350 ℃. At present, the initial temperature of the world's advanced J-class gas turbine reaches over 1600 ℃.

3、 Classification of gas turbines

1. Heavy duty gas turbine

The design of the components is relatively heavy, and the main purpose of the design is not to reduce weight. It can achieve long-term safe operation when using economical materials. The mass per unit of power is 2-5 kilograms per kilowatt.

2. Light gas turbine

Made of relatively good materials, with a compact structure and light weight, the mass per unit power is less than 2 kilograms per kilowatt.

(1) The axial assembly method is adopted, which means that the entire stator is not completely horizontally divided, only partial stators such as compressor cylinders are divided into two halves for disassembly and assembly. (2) The rotor is generally supported by rolling bearings. Part of the technology is inherited from aviation engines, such as the LM2500 series gas engines, which are converted from aviation to combustion engines.

3. Micro gas turbine

Design the gas turbine and generator as a whole, with a small volume and light weight. Structural features: (1) Adopting radial flow impeller machinery. (2) Some units also use air bearings that do not require lubricating oil.

In the field of industrial gas turbines, there is generally no globally unified technical standard to classify gas turbines. The classification of gas turbines is usually determined by various manufacturers based on factors such as power, performance, application areas, and technical characteristics of their products. Therefore, different manufacturers may use different classification methods and standards, and there is no universally applicable standard system for all industrial gas turbines. The following classification based on power levels is provided for reference:

- Heavy duty gas turbine: power range above 100MW;

- Medium sized gas turbine: power range from 10MW to 100MW;

- Small gas turbine: power range from 1MW to 10MW;

- Micro gas turbine: power range from 100KW to 1MW;

- Ultra micro gas turbine: power range below 100KW.

4、 Characteristics of gas turbines

1. Maximum efficiency, optimal benefits

With the continuous advancement of high-temperature materials and the use of cooling blades in turbines to continuously improve cooling efficiency, the initial temperature of the gas before the turbine is gradually increasing. In addition, the development of compressors with decreasing stages and increasing compression ratios, as well as the improvement of the efficiency of various components, have continuously improved the efficiency of gas turbines.

2. Small size, easy to use

The design and construction of gas turbine power components are derived from aviation engines, with a simple and compact structure. Compared with traditional equipment, gas turbine equipment has a smaller scale and volume, occupies a smaller area, and is easier to maintain or move than traditional boilers and steam turbines.

3. Reduce coal consumption, clean and environmentally friendly

Gas turbines can use a wide range of fuels such as natural gas, propane, oil well gas, coalbed methane, biogas, gasoline, diesel, kerosene, alcohol, etc. By controlling the generation of NOx during combustion or conducting tail flue gas denitrification when NOx is generated and discharged into the waste heat boiler, ultra-low NOx emissions can be achieved, and resources can be fully recycled to truly achieve low emissions. With the gradual maturity of hydrogen production technology and hydrogen blending combustion technology in gas turbines, gas turbines will gradually transition to a zero carbon emission era dominated by hydrogen fuel in the future.

4. Low noise, safe and reliable

The working principle of gas turbines makes their operation smoother and reduces the noise generated by mechanical vibration. This advantage makes the application of gas turbines more suitable in urban or densely populated areas, reducing interference with surrounding residents. At present, advanced gas turbines can monitor the working status of the gas turbine in real time through the use of digital communication networking, machine learning and other technologies, and guide customers in maintenance and repair, greatly improving the safety and reliability of gas turbine operation.

5、 Key Technologies of Gas Turbine

1. Key Technologies of Compressor

Pneumatic high load and high-efficiency design technology; Aerodynamic performance high stability design technology; Pneumatic multi-stage matching design technology; Numerical simulation and verification technology for multi-stage aerodynamic performance of the whole machine; Rotor structure and strength design technology.

2. Key technologies of combustion chamber

Combustion field organization design and testing technology; Design technology for flame tube wall structure; Nozzle design and testing technology; Cooling, protection, and strength design technology for high-temperature components; Low emission combustion design and testing technology; Wide range stable combustion design and testing technology; Numerical simulation and validation techniques for combustion fields.

3. Key Technologies of Turbine

Design and testing technology for air cooling of moving blades, guide vanes, and discs; Design and experimental technology of blade steam cooling; Analysis and testing techniques for temperature field, stress field and strength life of blades and discs; Performance analysis and design technology for turbine stages with mixed cooling airflow; Numerical simulation and verification technology for multi physics fields of cooling blades; Rotor structure and strength design technology.

4. Key technologies of important systems in gas turbines

Design, performance analysis, and debugging techniques for cooling air systems; Advanced control system components, controllers, and control laws; Starting system technology; Bearing and oil system technology.

5. Gas turbine material technology

Development of oriented and single crystal high-temperature alloys with strong resistance to thermal corrosion; Improvement of high-temperature alloy material system; Performance testing of high-temperature materials under close range service conditions for 5000-10000 hours; Research on the mechanical properties of large-sized castings under near service conditions; Research on the antioxidant and thermal corrosion resistance of large-sized castings; The pull rod is made of CrMoV high-strength steel.

6. Gas turbine process technology

Manufacturing technology of complex structure ceramic cores; Manufacturing technology of high-strength and heat-resistant ceramic mold shell; Large scale directional crystallization and single crystal blade directional solidification technology; High temperature turbine blade processing, welding, heat treatment, testing and other processes; Blade coating technology; Burner manufacturing technology; Engineering research on gas turbine blades; Manufacturing specifications and acceptance standards for gas turbine blades; Manufacturing technology for large turbine disks; Manufacturing process of high-strength steel tie rod.